September 2009

With the bike painted and largely assembled it was now time to add the finishing touches and attend to the job we'd been avoiding for six months - the electrics. |

| |

|

|

Instruments

This is called "style". There is no other explanation for it. Why a motorcycle company would choose to manufacture bikes with purple instrument bezels is something which will probably be forever lost to us. |

| |

|

|

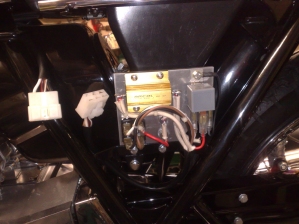

The solution

The Benelli 2C carries with it a reputation for extraordinary electrical unreliability. We decided to largely throw the whole lot away and start again with something simpler and more rustic. What you see here is a big aluminium heat sink, a bridge rectifier (takes the AC current from the dynamo and converts it to DC), a zener diode to limit the voltage to 7 volts, a nice big ballast resistor for the trickle current back to the battery and a simple relay to override the ballast resistor when we switch the headlights on. Simple huh? So far, three bikes and 5,000 kilometres - all running well. |

| |

|

|

Finished at last!

This was the actual day she rolled out of the shed to see sunlight for the first time. I'm a bit biased but I think it looks great just standing still. |

| |

|

|

The Photo Shoot

No restoration is complete before the big photo shoot. There is a good reason for all this. Sadly, the first day the bike heads out onto the road it starts to deteriorate and will never quite look the same.

|

| |

|

|

What next?

During the restoration of my bike we were actually restoring three of these machines. The first thousand kilometres on each will, no doubt, have its share of headaches.

I will write an overview of the bike after we've completed the run-in period.

|

|

|