Things that stop you by the side of the road (and how to prevent them)

If you are restoring a Benelli 2C you, like us, probably found it with little mileage on the clock apparently abandoned by some previous owner. You scratch your head and wonder why. Every one of our bikes (ten of them!) had prematurely failed electrical systems. The engines were generally fine. So how do you correct this?

(1) Rewire the whole bike. Bite the bullet. Do it. It's a simple electrical system. Don't do it and it will let you down. Trust me on this!

(2) Install a Rooster Booster RR6-150 electronic regulator rectifier. This involves a little bit of electrical knowledge and some soldering and shrink-tubing but I managed it so you can! Ask someone how to isolate the AC feed from the generator coil and take it to the RR6-150. Easy as that. Rely on the old regulator in the headlamp and ... well ... it's 40 years old now. Time it was replaced.

That's the electrics sorted.

After the first thousand kilometres (see previous page) I waxed on about the virtues of having the old San Remo rims rechromed to maintain originality. In a word, DON'T! I was wrong about this. I was riding behind my friend Michael when his rechromed original rim split in half. Happily he stopped the bike safely but repeated polishing and acid stripping had left the rim very, very thin. If the rims are old and rusty it is cheaper and safer to get a set of new polished alloy rims with virtually the same profile as the old San Remos from

Central Wheel Components in Birmingham. Highly recommended.

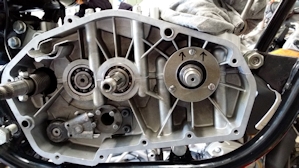

We've only had one issue which forced a Benelli home on the trailer. Jim's Benelli lost spark completely during a ride. Up on the bike ramp we found that the left hand side crankshaft bearing had moved outwards pushing the crankcase seal out with it. The crankcase seal ended up floating around inside the rotating magneto and snagged the coils - tearing them apart. Quite a mess. When we examined the bike, the right hand side bearing and seal were starting to do the same. A conversation with the guys on the Benelli forum revealed that the 2C regularly does this under race conditions and they take the following action to ensure it doesn't occur:

(1) They use crankshaft bearings with thin "o"-rings in the outer shell. This prevents them from rotating in the crankcase housing.

(2) They use bearing mount on the crankshaft to ensure the crankshaft-bearing fit is tight.

(3) They use the correct 10mm wide outer crankcase seals (7mm are easy to find, 10mm require a bit of effort. A good bearing shop will make the effort, a bad shop will tell you the 10mm seals don't exist).

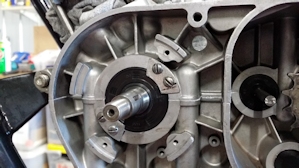

(4) They retain both the left and right hand seals by attaching an arrangement of tabs and retaining washers (see below)

I have to stress that only one bike has displayed this problem and when we stripped it down we found it had quite a well worn crankshaft on the bearing faces - perhaps this bike was one of the early models with the bad bearings. In any case the modifications made have prevented a recurrence and I would probably make the same mods on any future engine rebuild. Most Japanese two strokes use seal retainers and this is a good recommendation (did I say that?).

|